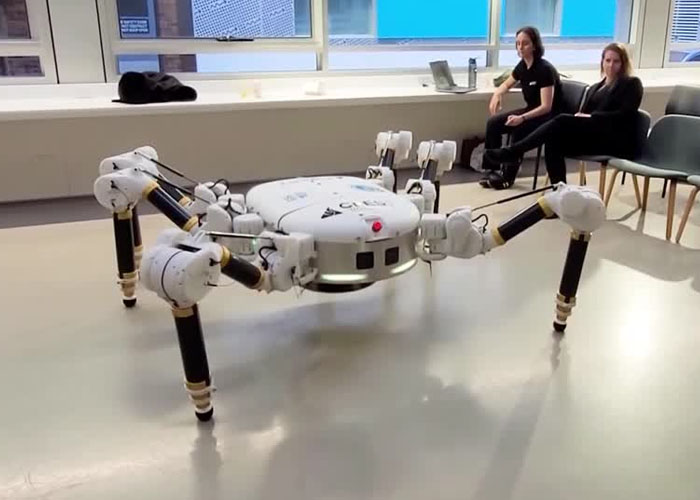

SYDNEY (Reuters) By combining robotics with 3D printing, a spider-like, semi-autonomous prototype robot called Charlotte could revolutionise building on Earth – and one day, even on the moon – say its developers.

Named after the character in the children’s novel Charlotte’s Web, the concept of Charlotte was born from a collaboration between Clyde Webster, founder and CEO of Crest Robotics, and Jan Golembiewski and Jonathon Steggles Mendez, co-founders of Earthbuilt Technology.

“We were discussing how you would actually implement these automated versions of the technology and the techniques, and we came up with the concept of Charlotte, which was a large legged robot,” Webster told Reuters from Crest Robotics’ headquarters at the Australian Innovation Centre in Sydney.

Made from a combination of aluminium, carbon fibre and 3D-printed plastics, Charlotte’s six legs will extend to over 5.5 metres, allowing it to straddle the walls of two-storey buildings while printing out the structure.

Using the bound earth building method, Charlotte takes up earth — ideally from the building site itself — compresses it through an extruder, and knits a membrane to keep the compressed earth in place, instead of using carbon-intensive methods like cement or fired bricks.

The robot then prints the compressed layers on top of each other like a bricklayer, creating structures and design features such as curves, arches and domes. This surpasses regular construction limitations and offers architects greater design freedom, the team said.

Webster and Golembiewski believe that Charlotte will be a game-changer for the construction industry.

“Charlotte and Earthbuilt in particular, the core technology within Charlotte, will be a game changer wherever it goes in the world. It will make construction really, really cheap… And it’ll also make it carbon free,” said Golembiewski, adding that the technology represents a major shift in decarbonising the construction sector.

Not content with tackling housing shortages and carbon emissions at home, Webster and Golembiewski say Charlotte’s ability to utilise local materials makes it an ideal candidate for lunar construction.

“Charlotte and the Earthbuilt building method — it’s actually perfect for construction on the moon, because by weight, 99% of the structure can just be the material you find around you. And for lunar construction, you can’t take a lot with you,” added Webster.

Having received a grant from the New South Wales state government’s Space+ program, the next step is finding project partners to integrate the system into existing construction workflows.

“It opens up the pathway for everybody. It is a great enabler,” Golembiewski said. “This thing does not have the limitations that humans have.”